C-180

MCHE Condenser for R410a

Product

This coil is specially designed for use as condenser in HVAC/R-applications, such as: chillers, condenser units, remote condensers, residential AC, commercial AC, AirHandlingUnits, Transportation and special units. The coil can be used for pressures up to PS=45bars and therefore optimized for R410a, but can also be used for all other refrigerant with same advantages. The coil can be customized in size and capacity to match the requirement of the specific application, giving compact units with high efficient cooling solution. The unique design of the MPE-tubes and the louvered fins together with the special technology of the full brazed aluminium coil gives advantages such as low weight, reduced refrigerant charge, low depth, reduced pressure drop (noise level) and improved efficiency. All Aluventa coils are designed for customer setup in order to achieve the optimum solution and highest efficiency

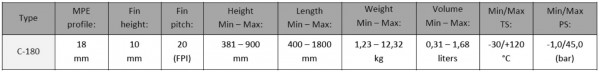

Technical spec.

Refrigerants

The coil is approved for group 1 and 2 refrigerants up to PS = 45bar(g), such as R410a, R717, R22, R134a, R290, R407c, R744, R404a, R507A. Use with propane and ammonia is recommended only with coated coils.

Materials

The Heat Exchanger is an all-aluminium product made of brazable alloys from the EN/AW 3000 series.

Copper connections are Cu-pipes according to EN 12735 (Copper and copper alloys – Seamless, round copper tubes for air conditioning and refrigeration).

Coating

The coil is available with Electrofin® e-coating for extra corrosion protection. This coating solution fulfill market standards and Aluventa quality requirements. Information on selection and recommendation can be found in the Aluventa Selection Guideline.

Connections

The coil is available with standard copper tube connection in OD size: 12,7 and 16,0. The connection can be selected in 0°, 45° and 90° angles. The copper tube connection are selected in accordance to EN 12735. The Cu/Alu joint is protected with rubber sleeves to prevent galvanic corrosion.

Approval

Approvals PED 2014/68/EU for use with group 1 and 2 fluids (the coils are covered by article 3 section 3 in the PED 2014/68/EU). UL 207 (except from Ammonia (R717))

Leak test

The coil is pressure and leak tested using Helium mass spec. technology. The test is carried out at 50 bar as part of the quality control. The coil can be delivered sealed with a pressurized protective gas.

Quality

Aluventa A/S is an ISO 9001 certified company (DS/EN ISO 9001:2015). All coils are produced under the Aluventa advanced Quality System to ensure a consistent high quality level. All products and materials are recorded with full traceability according to requirements of PED 2014/68/EU.

Coil selection

The coil can be selected and designed using the Aluventa Simulation Software AluHex. Please contact Aluventa for support on simulation, selection and design.

Documentation

Further information and documentation is available in form of:

• Aluventa Design Guideline

• Aluventa Selection Guideline

• Aluventa Product Specification Type C-180

• Aluventa Installation and Maintenance Manual

All documents are available for download at www.aluventa.com

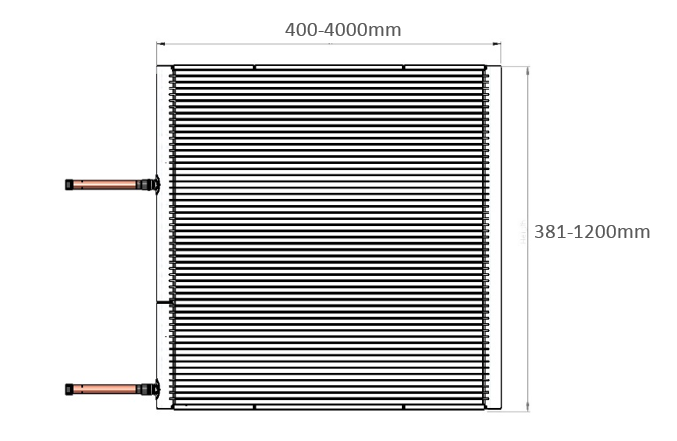

Condenser size

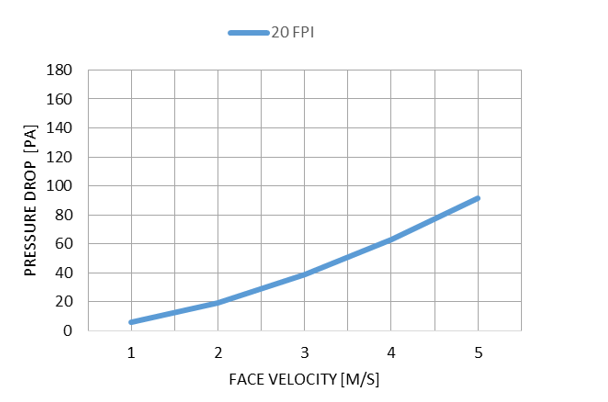

Airside pressure drop